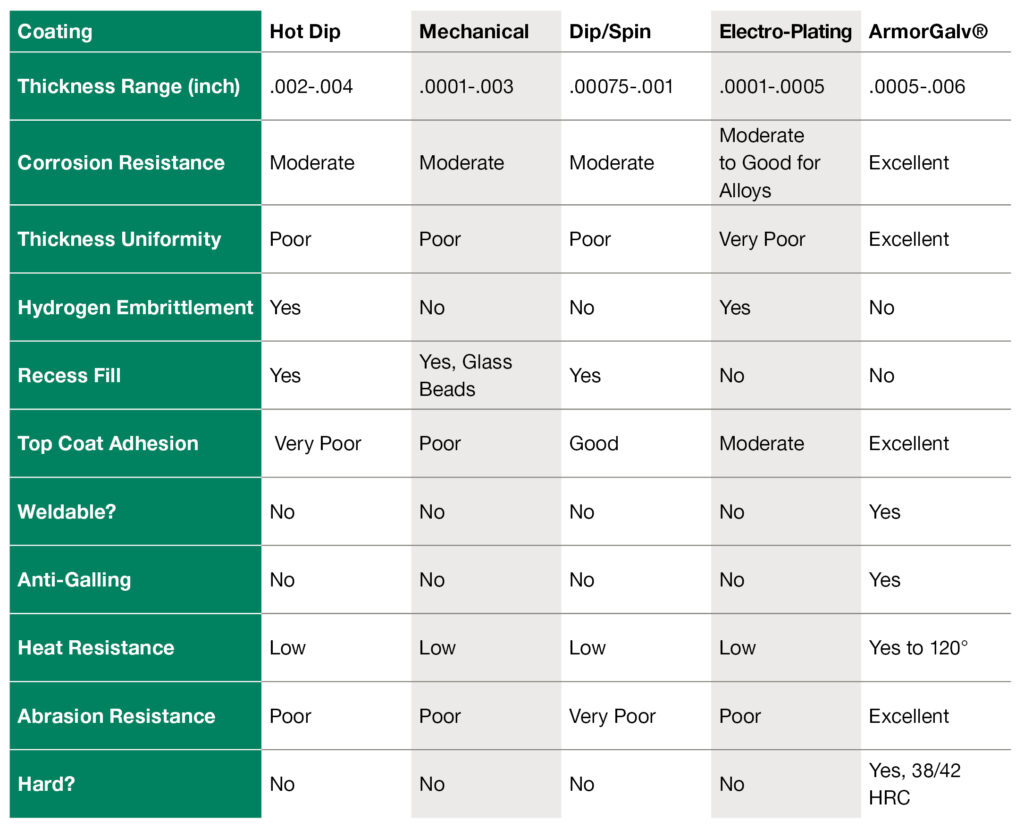

The Distek™️ company developed the ArmorGalv® Thermal Zinc Diffusion coating technology in 1993. This process is an updated and innovative 21st-century form of the well-established Sherardising process.

The ArmorGalv® technology uses a new saturating mixture with unique properties. The process is based on mixing metal parts with the patented dry alloyed zinc-powder and dry heating inside the oven at 320-470° C while mixing them in slowly-rotating, sealed containers.

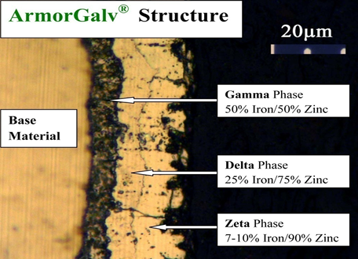

The process involves the diffusion of dry alloyed zinc powder into the metal parts’ surface, resulting in multiple layers of Zn/Fe Alloy from the superior corrosion resistant Gamma layer to a compact Delta layer followed by the Zeta layer.

Each layer is harder and more corrosion resistant than the previous.

The second major innovation of the ArmorGalv technology is the passivation (finishing) process, which involves patented chromate-free solutions. The passivation is an integral part of the coating process, strengthens the corrosion resistance, and making the part’s surface hard and smooth. The coating’s characteristics are perfectly combined with all types of finishing coverings and paints.