In 2010 ArmorGalv Australia was founded as the Australian licensee of Distek’s ground-breaking Thermal Zinc Diffusion technology. A process used by leading global enterprises such as the US Navy, Caterpillar, and Mercedes Benz.

In Australia, it was first used to coat roadside safety posts but soon found widespread use in industry.

The Thermal Zinc Diffusion (TZD) process ensures the anti-corrosion zinc layer penetrates the steel substrate, creating a deep diffusion when compared to other superficial Zinc treatments such as hot-dip galvanising. TZD provides:

- A uniform coating thickness, which can be prescribed between 20 and 120 microns.

- A greater surface hardness (exceeding Rc 45).

- Superior corrosion protection – up to ≥1000 hours in salt spray testing.

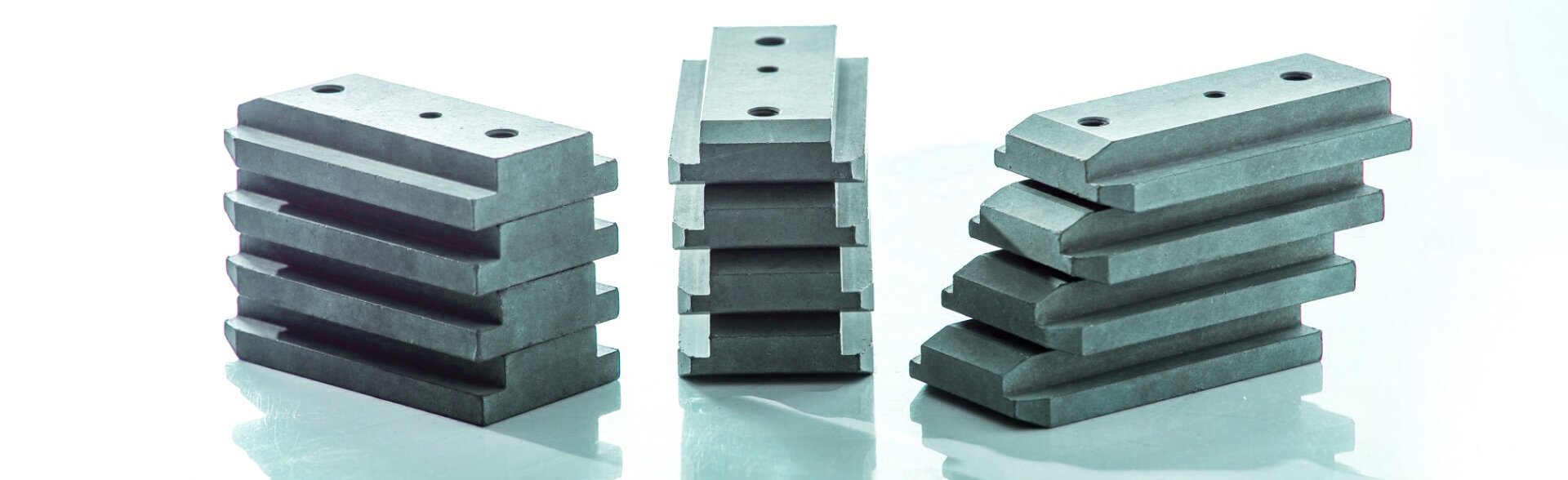

Over the past decade Thermal Zinc Diffusion has been applied to threaded products, fasteners, bars, springs, and hollow tubular products.

Parts that have been used on wind farms, underground mines, securing rock walls alongside freeways, road tunnels, power transmission infrastructure, and railway lines all round Australia.

Serving you

At ArmorGalv Australia we pride ourselves on our service.

- We have the flexibility to meet short production deadlines

The scale to process large volumes of parts - And a service ethos that puts customers at the heart of all we do. From enquiry through to post-processing experience.

It is why we have so many long-standing customers – still with us more than a decade later.

To find out how we can provide a uniform zinc coating with the best anti-corrosion protection please contact us.