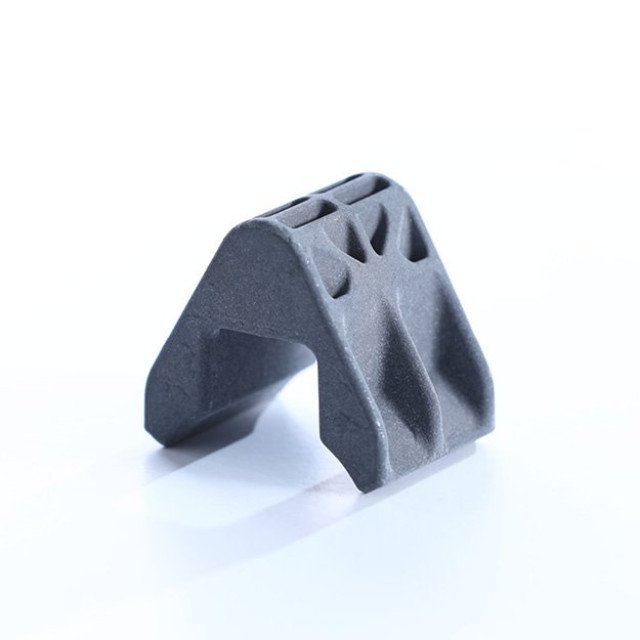

Our innovative Thermal Zinc-Diffusion coating method provides better quality, stronger corrosion resistance, maximum accuracy, and an attractive cost-benefit ratio. The whole process is ecological-friendly, with no acids, and nothing is thrown into the sewer. Our technology achieves better results compared to other zinc-coating methods.

About ArmorGalv

What we do

Over the last decade ArmorGalv coated fasteners, bars, springs, and rail clips have been used on wind farms, underground mines, securing rock walls alongside freeways, road tunnels and railway lines amongst many other applications.

Why ArmorGalv?

Higher quality

Why ArmorGalv?

Environmentally friendly

Why ArmorGalv?

The Environmental choice

ArmorGalv‘s duplex corrosion-protection performance approaches stainless steel at a fraction of the cost. Since the entire process is ecologically-clean, there are no additional costs in handling environmental issues and wastes. Our lines are based on a closed system and include a purification facility for reusing the water. The use of electricity is only while the line is running, leading to significant energy usage savings. All those unique characteristics make our technology the environmental choice.

ArmorGalv clients around the world

clients11

clients17

Sandvik

clients18

Pandrol

PCA

clients15

GSS

IDE

clients16

clients10

clients5

clients20

clients1

clients3

QPS

clients13

clients7

clients2